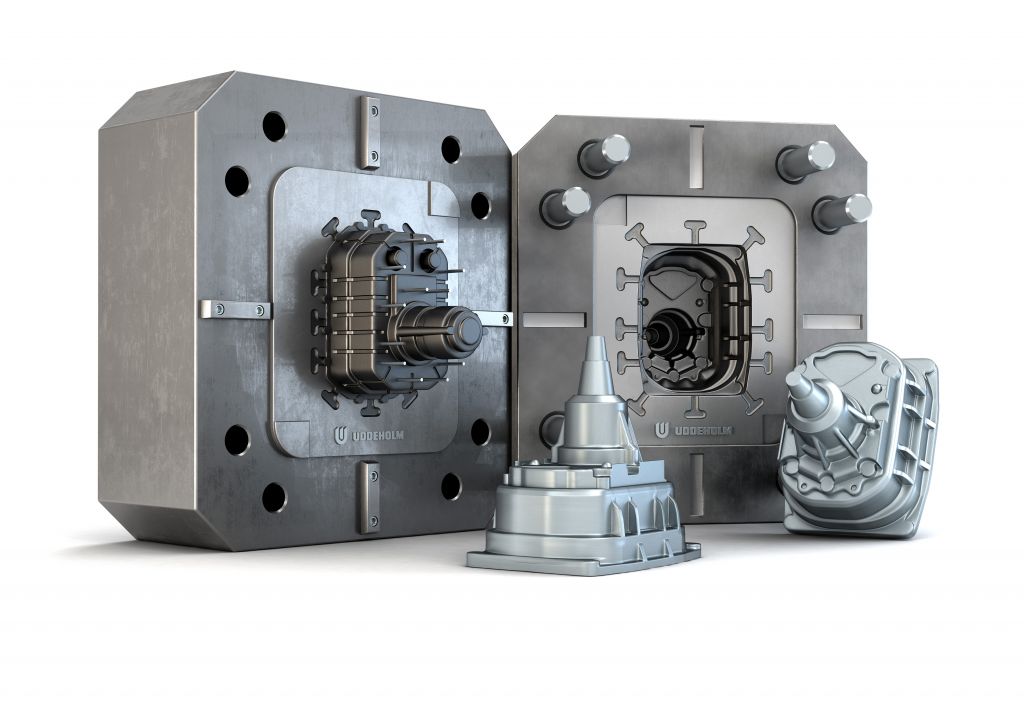

In the hot forming industry, and namely in aluminium and zamak die casting, the preparation of mould parts is crucial to preserve dies, core slides and core pins from wear and thermal fatigue.

To achieve high surface hardness as well as wear and thermal fatigue resistance, over the years, Lafer’s R&D team has designed a range of technical solutions that provides not only for the selection of the most suitable coating, but also for the optimization of surface finishes and for mould part hardening.

In die casting, the mould surfaces of dies, core slides and core pins are subjected to wear due to the distinguishing features of this hot forming process.

The speed and pressure at which the molten alloy is injected into the mould cause stresses that trigger abrasive wear on the most exposed operating surfaces.

During die casting, moulds are subjected to significant stress and high temperatures due to the high-pressure injection of metal alloys.

In these cases, die soldering – that is, a defect due to which the molten alloy sticks to the mould surface – is likely to occur. As a result, ejection of the part formed by the mould fails to meet design specifications.

The nature of die casting processes involves cyclical thermal stress in the mould due to the alternation of molten metal injection/formed part ejection phases. Alternating thermal conditions implies a fluctuation between surface tension and compression states, which results in the deterioration of mould parts due to thermal fatigue.

Such deterioration is evidenced by surface cracks in the mould.

AlCrN coating deposited using arc technology, combined with ion nitriding in a single cycle.

Excellent for aluminium and zamak die casting for dies and core slides subjected to high pressure.

ANTI-ABRASION

METALIZATION RESISTANCE

TERMAL FATIGUE RESISTANCE

INCREASE IN HARDNESS

AlCrN coating deposited using arc technology.

Excellent to improve the hardness and the adhesive wear resistance of dies, core slides and core pins in aluminium and zamak die casting processes.

ANTI-ABRASION

METALIZATION RESISTANCE

TERMAL FATIGUE RESISTANCE

INCREASE IN HARDNESS

DO YOU WANT MORE INFORMATION?

Fill in the form and send it back to us.

You will be contacted shortly by a member of Lafer’s R&D team.