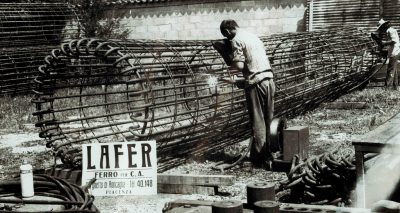

Established in 1986, Lafer Rivestimenti is an ISO 9001 certified company that provides PVD, CVD and DLC coating solutions to solve wear and friction issues affecting tools, moulds and components by using the latest technologies available on the market.

120

EMPLOYEES

19

COATING UNITS

5000

SQM

13

R&D ENGINEERS

EFFICIENCY – IN OUR WORK, OUR SERVICE LEVELS AND RESEARCH

The Lafer R&D team is committed to provide a comprehensive consulting service by developing customized processes.

Lafer provides coatings for on milling cutters, drills, taps, reamers and inserts using the arc and magnetron sputtering technologies for application in the traditional fields of chip removal.

Today Lafer provides a service that guarantees:

- the reduction of friction and operating temperatures

- the reduction of lubricant use

- the increase of cutting parameters

- a reduction in production costs.

Lafer’s coatings provide multiple advantages in the forming and moulding industry.

First and foremost, they extend the service life of moulds, as coated materials require significantly less ordinary maintenance and resulting production downtime.

The component department is Lafer’s latest achievement.

Equipped with specialist coating techniques, it relies on tribological analysis to achieve the best performing coatings directly in-house.

The performance of coated materials is enhanced by reducing friction coefficients, improving wear and corrosion resistance, and increasing surface hardness.