In chip removal processes, the main goal is to facilitate chip evacuation while avoiding thermal shocks as much as possible to increase the tool’s service life.

In this area, Lafer offers a coating and treatment solution that ensures a reduction in friction and operating temperatures as well as lubricant use to achieve the best quality of the finished part.

Turning is one of the heaviest and most challenging chip removal applications – being a continuous cutting operation, the cutting edge must withstand very high temperatures and stress.

It is therefore crucial for these coatings to be thick, reduce any internal stress and have a high oxidation temperature. Another key feature of coatings for turning is a compact structure that combines high toughness, hardness and wear resistance.

The milling process is generally comprised of two steps – roughing and finishing.

In the former, the tool must withstand high stress to remove the largest quantity of material in the shortest time possible. During finishing, the tool operates to remove a smaller volume of metal and obtain a finished product that is suitable in terms of dimensions, tolerances and surface finish.

AlTiN coating deposited using magnetron sputtering technology.

Excellent for chip removal, milling and drilling of quenched steel.

WEAR RESISTANCE

OXIDATION RESISTANCE

COF REDUCTION

INCREASE IN HARDNESS

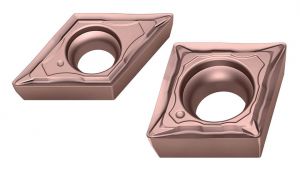

Multilayer AlTiSiN coating deposited using arc technology.

Excellent for chip removal with inserts on difficult materials, such as superalloys and alloy steel.

WEAR RESISTANCE

OXIDATION RESISTANCE

COF REDUCTION

INCREASE IN HARDNESS

AlTiSiN multi-layer coating deposited with HiPIMS technology.

Suitable to maximize the yield of solid carbide cylindrical tools in the machining on medium and high hardness steels.

WEAR RESISTANCE

OXIDATION RESISTANCE

COF REDUCTION

INCREASE IN HARDNESS

AlCrN multi-layer coating deposited with HiPIMS technology.

Suitable for maximizing the yield of cylindrical tools for dry and wet chip removal in steel processing.

WEAR RESISTANCE

OXIDATION RESISTANCE

COF REDUCTION

INCREASE IN HARDNESS

Multilayer ZrN coating deposited using arc technology.

Recommended to optimise the performance of tools and inserts in the machining of non-ferrous materials prone to sticking.

WEAR RESISTANCE

OXIDATION RESISTANCE

COF REDUCTION

INCREASE IN HARDNESS